vertical cooling water pump

LC vertical cooling water pump are "engineered to order" large flow vertical pumps for industrial pumping needs and sump design, with semi-open or closed cast impellers available in sizes starting from 650 mm (26") impeller diameter and nq 75 (Ns 3'870). They are mainly designed as cooling water pumps for thermal power and combined-cycle power applications but can also be used in water or other industries.

High pump efficiency

Modern fabricated suction bell and bowl casing incorporating swirl break for stable pump performance curve

Semi-open or closed cast impeller design for best fit and optimum efficiency

Segmented elbow to optimize pump efficiency

Optional full pull-out construction to reduce lifting crane capacity and ease maintenance

LC vertical cooling water pump is specifically designed as circulating water pump for the following fields:

Cooling water pump in utility thermal, nuclear, gas-fired combined-cycle power plants and industrial power stations

Water supply

Irrigation

Flood control and drainage

General water service

Cooling water pump for refining and seawater intake pump for open rack vaporizers in LNG regasification terminals

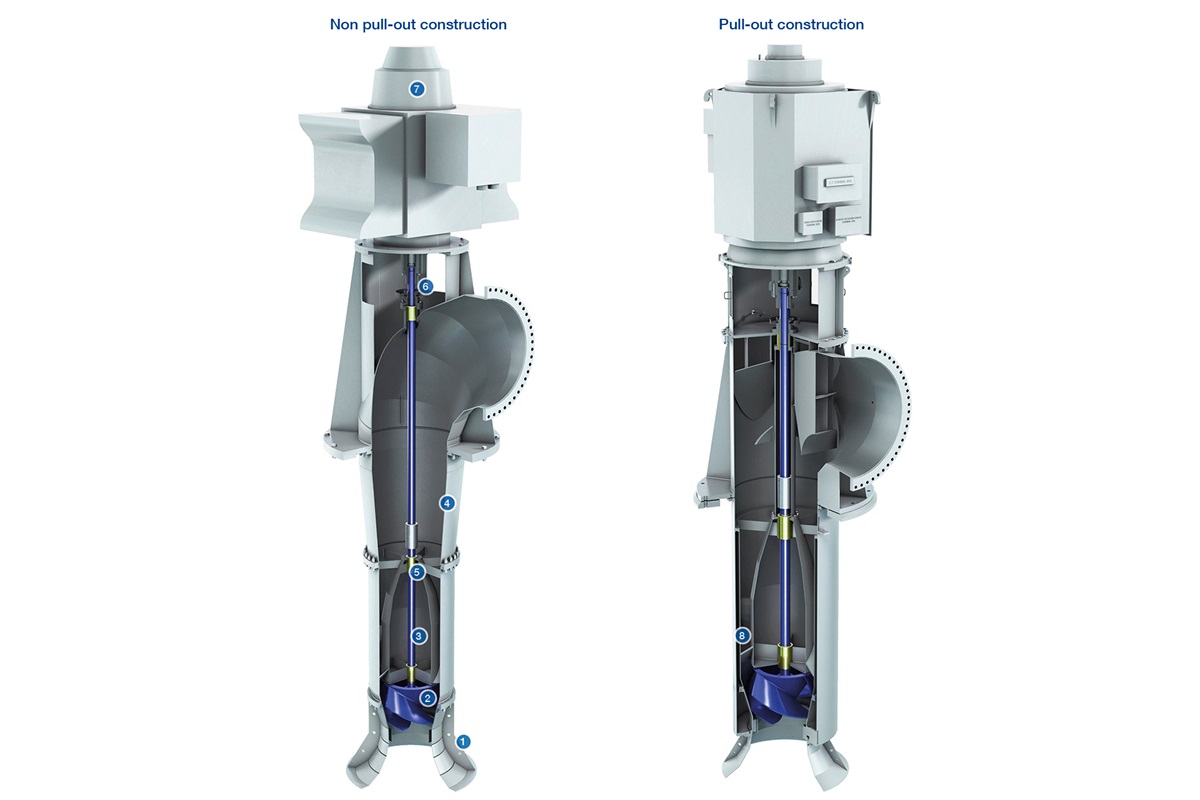

1. Modern fabricated suction bell and bowl casing

Incorporating flow straightener for stable pump performance curve

Tailor-made bowl diameter to optimize pump selection and efficiency

2. Modern semi-open or enclosed cast impeller design

Best hydraulic fitting and optimum efficiency. Fabricated impeller construction optional

3. Individually sized pump shaft

Sized for maximum torque. Shaft protection sleeves included as standard

Line shaft connected by split ring, key and sleeve couplings to ease maintenanc

4. Fabricated column assembly and discharge head

Column assemblies have integral spider to improve stiffness

Segmented elbow to optimize the pump efficiency

Above- or below-ground discharge to fit the site requirements

5. Product lubricated radial bearings

Cutless rubber (phenolic backed) bearing bushings as standard in bowl/lineshaft, other material options are also available

Two bearings bushings included in the bowl for increased rotor stability

6. Packing shaft seal

Reliable sealing and simple maintenance

7. Thrust bearing

Thrust bearing can be provided either in the pump or within the motor

8. Optional full pull-out construction

Reduces the crane lifting capacity required

Significantly improves the maintenance turnaround time